Counterframes guaranteed

fifteen years

Ultra-tested processes and clinching

In this article we will tell how all our countertops are tested by the Giordano Institute, also telling the tradition of the institute in high quality testing.

In detail we will clarify how the tests are aimed to the improovement of all the production processes of the countertops themselves, to obtain

counterframes guaranteed

fifteen years

Why did we entrust the Giordano Institute for our tests?

The answer is simple and effective: the mission of the institute is to “promote quality in industry” by offering high added value services alongside companies that test the conformity of their products.

The Giordano Group affords serious and scrupulous companies who only want the best for their customers.

But we want to give our users maximum transparency by answering the following question:

What does the guarantor guarantee? Or What guarantees us that the services offered by the Giordano testings are really of superior quality?

The answer is in the following data:

Over fifty years of testing; The Giordano Institute has been testing industrial products since 1959 and has gone through an entire period of continuous industrial revolutions, continuously innovating its own methods to meet the needs of businesses, even though the digital revolution imposes and imposes Keep changing.

Over 20 multidisciplinary testing laboratories

Over 300,000 certificates issued.

Regarding Filmar, the Giordano Group performs the following “Failure Test” for us:

- Tests to determine the causes of breakage.

- Tests for determining the causes of corrosion.

- “Welding” checks, that is, of clinching.

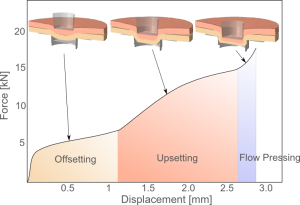

The following figure describes in detail the clinching process, a process that takes place through the pressure of a punch applied to two or more of metallic material layer resting on a matrix.

The third stage is the most delicate one, and it can also be performed by applying a light heating that binds most of the metal bound.

The clinching attachment points are those most stressed during the tests to reach the breaking load, so the greater the applied load to reach the breaking limit, the better the clinching will be.

The structure of the counterweight Filmar is a set of parts designed to support each other.

Such construction, and a perfect clinching have allowed our subframes to achieve excellent results in load-break test, test certificate from the institute.

Corrosion tests, on the other hand, allow you to understand how clinched surfaces are perfectly bonded and if there are small air gaps that can favorite attack of corrosive agents.

Here too, our subframes have achieved excellent results, certified by the Giordano Institute.

The tests are completed by the specific verifications carried out on the clinching points (welding tests), carried out through stress tests aimed to understand the degree of punctual division of the metallic layered strata.

Even for these last tests, our products have been excellent in obtaining quality certification from the Giordano Institute.

The best guarantee that we offer to our installers is needing to continually improve our countertops, subjecting them to more and more testing.

But Filmar does not just have to test its products continuously, we claim that testing them is one of the most serious and reliable institutes of testing that can guarantee maximum results: the Giordano Institute.

Filmar: improve every day more.