The entire range of “Filmar New Age” counterframes is manufactured using carefully selected top quality materials and state-of-the-art processing to ensure a high quality and long-lasting finished product.

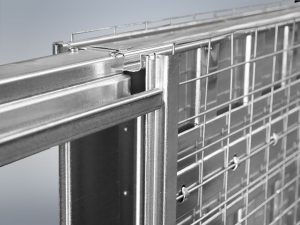

In particular, the side panels are made using thick galvanized steel sheets, vertically corrugated.

Corrugated covers are made by cold profiling of different thicknesses of coils (layers) of metal, aluminum alloy or steel, with subsequent galvanized or painted finish. The profiling process gives structural resistance to the sheet metal while maintaining, at the same time, lightness.

How are the corrugated steel panels obtained?

Through cold profiling, a process of bending a sheet metal strip at room temperature. It is a continuous operation and allows the realization of profiles of different sections. This operation is carried out through the deformation of a sheet metal strip that runs through a series of rollers with several passages, until the desired section is obtained. This process gives the panels greater strength and increases their impact resistance.