After talking about the application of clinic to our countertops, we will deepen in detailthe technique itself, highlighting some peculiarities practiced specifically by Filmar.

This is a method of assembling metal sheets or extruded pieces (such as our side reinforcements) cold-pressed.

The fusion is achieved by contacting the metal surfaces that are pressed between a die and a punch.

This process is particularly easy for joining large surfaces such as sheets, but is particularly complicated for extruded articles.

For the latter, in fact, it is necessary to provide a punch to be internally inserted into the piece, designed to fit the extrusion itself.

So let’s enter moore deeply into the argument and

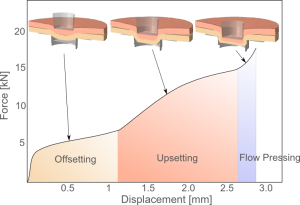

We go into more detail by showing the stages of clinching.

As we can see from the figure, the most important stage is the last (flow pressing) because it is in it that We create the welding deformation between materials.

It is this phase that completely differentiates the clinching from simple punching; here, in fact, the two metal layers are pressed in such a way that a blocking bend is formed between them.

It is therefore necessary to structure the punch and matrix in such a way that they can allow this slight dilation of the first layer in the second.

As already said, the process is carried out cold, but it is possible to heat slightly punch and die to favor a plastic effect during the contact between the two layers.

This effect most unites the materials by optimizing the solidity of the clinching.

We conclude the article by considering some simple technical data that make the idea of how difficult it is to achieve a good clinching.

- If in the third stage the pressure between the punch and die is too high or there is provided a heating to too high to materials, there is a risk of excessively thin the contact surfaces, creating a point of easy breakage in the structure.

- If, during the first two phases, the shape of the layers is not optimal, there may be voids that weaken the structure both chemically (internal air that corrodes the surfaces) and physically (easy break).

- One must continuously monitor the machines that perform the clinching so that these provide pressure and optimal contact with the surfaces.

- But this is not enough, a good manufacturer of industrial artifacts must “not trust themselves”, that is, it must strictly control their own product, to ensure only the best to their customers.

For this reason, we at Filmar have chosen one of the best Italian testing and control institutes, the Giordano Institute.

Next article we will go deep talking about tests performed on our products in this institute, paying attention to the guarantees offered by the Institute.

Filmar: quality understandable to everyone.