Today, Computerized Numerical Control (CNC) is a crucial part of production processes, capable of producing components precisely and repetitively with ease.

The computerized numerical control is a relatively recent concept in the world of the production and manufacturing industry. The first tools adapted to this type of control were the lathe and the milling machine, but before they were computerized, they were used for centuries with simple manual control. The first proof of the use of the lathe in fact dates back to 1300 B.C. in ancient Egypt, while the history of the milling machine is a bit foggy, some historians attribute to Eli Whitney the merit of the original motorized milling machine, others accredit inventors such as Simeon North, Captain John H. Hall, Robert Johnson, Roswell Lee and Thomas Blanchard.

During the 1940s, the idea of numerical control to automate machine tools using programming logic as a basis was first incorporated. Users began to modify manual machine tools to use them in numerical control using electric motors to control and move the machines, and perforated tapes for programming.

The first research on MIT numerical control

The next phase of development came after World War II, with the introduction of computerized Numerical Control systems. It was then that John Parsons looked for ways to improve the aircraft by making stiffened skins for them. This led to a series of research projects crucial to the Air Force that were hosted at the Massachusetts Institute of Technology (MIT).

The research began in 1949. After the preliminary research and planning phases, Professor J.F. Reintjes and his team designed an experimental milling machine. In 1958, five years later, he patented the control system “Motor Controlled Apparatus for Positioning Machine Tool”. This marked the official commercial birth of the technology.

This was the moment when lathes became more advanced with the advent of individual electric motors, which allowed greater reliability and power coupled with a smaller footprint. As the machines became more sophisticated, the G code replaced the perforated belt systems.

Definition of CNC machining

Now that we have retraced the history of the first lathes and milling machines, let’s talk about the modern use of these tools. CNC machines have a tool movement control program that determines the machining function on the block to be machined. During turning, it defines the rotational axes of the milling cutter. A milling machine with about three or five axes is controlled by a computer and is fully automated. The path that the cutter must take is indicated by the 3D file inserted in the computer, cutting the desired part from the block. This is one of the “subtractive” techniques that are inexpensive and fast in production.

What are the types of CNC machines?

CNC machines are designed to produce a wide range of items, which is why there are also different types of machines. All use the G code, which is the standard language of CNC machines, but each different type of machine serves a particular purpose. Here are just a few of them:

-Torni

-Router

-Milling machines

-Plasma cutters

-CNC laser cutting machines

-Bending and press-bending machines

The future of the CNC

As access to CAD becomes easier and easier, designs become more and more customised and complex. The future of the CNC is certainly bright and rather unlimited in appearance, but allowing easy access to it will help the world of invention and manufacturing to grow. Only time will tell how production will grow to the use of robotics and automated systems in almost all fields.

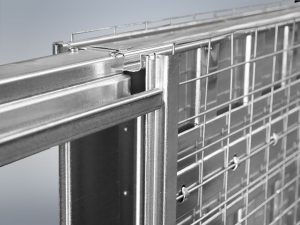

Filmar s.r.l. has always made use of CNC machines for the production of its sliding door counterframes. In particular, our plant is composed of various press brakes equipped with 3-axis numerical control that guarantee precise and constant bending, various industrial robots automatically controlled by a three-dimensional software simulator, which synchronizes perfectly with the movements of the press brake, allowing to accompany the sheets during the entire bending cycle.